Module Design

About Module

Design

Module was started in 2016 with the goal of making good design more accessible. Based in Pittsburgh, PA, Module is a vertically integrated modular housing company with a modular factory, a design and engineering arm, and a construction arm.

Module’s design team is flexible and scalable to handle multiple project sizes and varied scopes of work. Module has a national network of licensed architects and engineers and utilizes a streamlined BIM process to coordinate from concept to construction, both off-site and on.

Network of Licensed Design Professionals

Thoughtful, Energy Efficient Designs

Streamlined Process

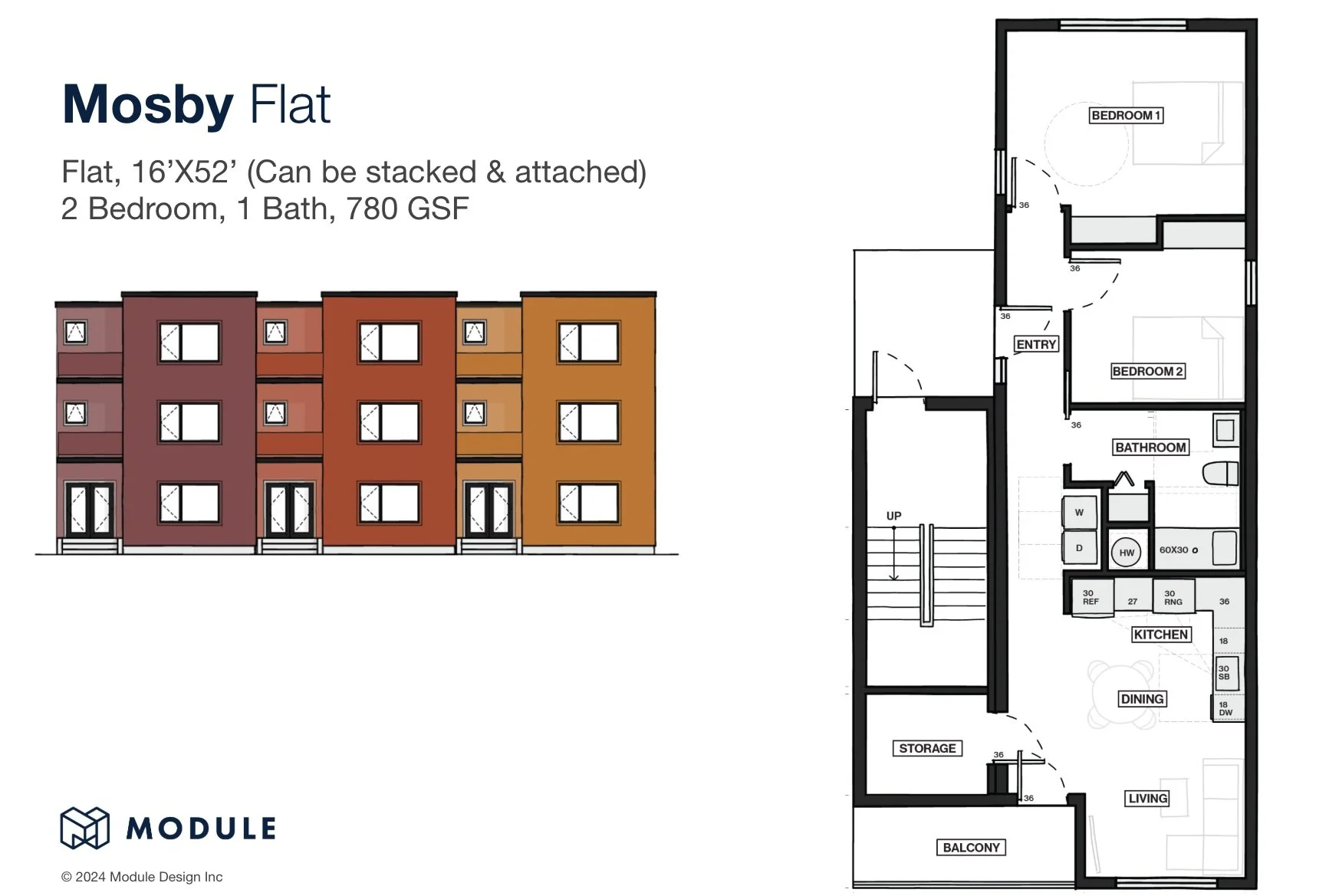

Standard Models, Built to Streamline Your Process

Our model catalogs are designed to make modular more accessible and simplify decision-making for developers. These models have been vetted by our team and shaped by feedback from developers, architects, and factory partners.

Each model is thoughtfully designed to balance flexibility with efficiency so you can move from concept to construction with clarity and confidence. Whether you’re building one home or many, our catalogs give you a strong starting point, without the need to start from scratch.

BIM

Module uses Building Information Modeling (BIM) to bring precision and efficiency into our design and manufacturing processes. BIM ensures that systems are successfully integrated into our buildings, performance is vetted and details are optimized before production begins.

What does this mean for our process and our people?

Fewer delays, less figuring things out in the factory/field, and a faster path to high-quality, sustainable homes.

Laborers can pull up a 3d model from the factory floor to fully understand how the components are coming together, even taking dimensions for reference.

Providing more information in a clear and straight forward way is critical to training a less experienced crew. Dynamic visuals provide the tools to fully understand the project.

We’re not your average manufacturer…

Explore our vertically integrated system: